Comprehensive Guide to Silicone Rubber Membranes for Business Applications

In the highly competitive landscape of industrial manufacturing and engineering, the selection of premium materials such as silicone rubber membranes can significantly influence operational efficiency, durability, and cost-effectiveness. Businesses seeking reliable solutions for their vacuum systems, sealing, and membrane needs increasingly turn toward specialized products designed to withstand harsh conditions while maintaining optimal performance.

Understanding Silicone Rubber Membranes: The Basics

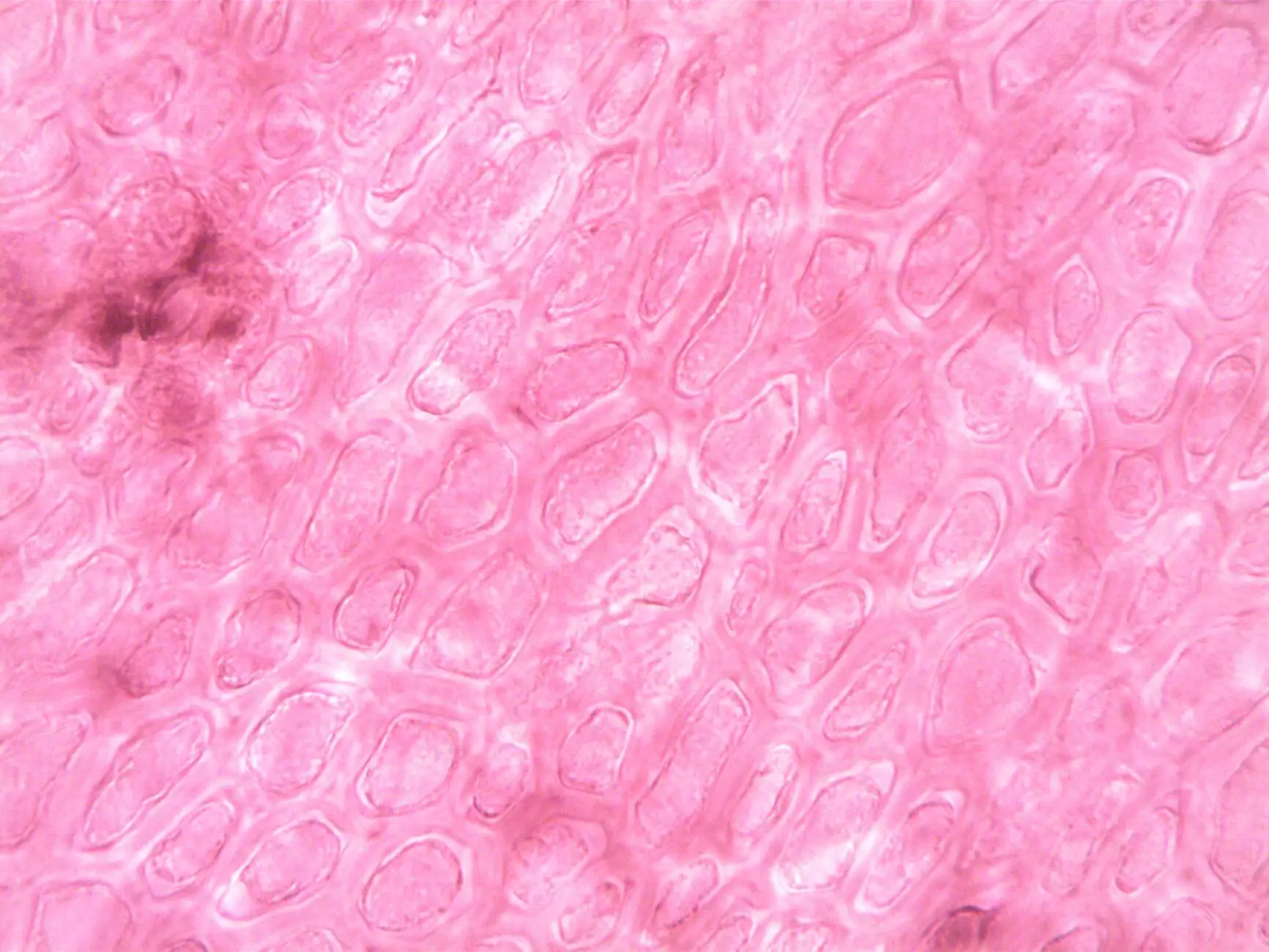

A silicone rubber membrane is a versatile, durable, and flexible material used extensively across various industries. Known for its excellent thermal stability, chemical resistance, and flexibility, silicone rubber membranes are invested with properties that make them ideal for sealing, insulation, and flexible diaphragms in complex systems.

What Are Silicone Rubber Membranes?

Silicone rubber membranes are thin sheets or sheets-like structures composed primarily of high-quality silicone elastomers. They are fabricated to precise dimensions and tailored with specific features like reinforced edges, coatings, or custom shapes to fit specific operational needs.

Key Properties of Silicone Rubber Membranes

- Exceptional Temperature Tolerance: Ranging from -50°C to +230°C, allowing use in extreme conditions.

- Superior Chemical Resistance: Resistant to acids, bases, and many solvents, ensuring longevity in challenging environments.

- Flexibility & Elasticity: Maintains flexibility over a wide temperature range without cracking or degrading.

- UV & Ozone Resistance: Suitable for outdoor applications where exposure to sunlight and ozone is inevitable.

- Biocompatibility: Safe for use in medical or food-grade applications, depending on formulation.

The Significance of Silicone Rubber Membranes in Modern Industry

In contemporary business practices, silicone rubber membranes serve as a critical component in multiple applications. Their versatility, combined with impressive durability, means they are indispensable in sectors such as vacuum technology, aerospace, medical devices, automotive manufacturing, and consumer goods.

Advantages Over Other Membrane Materials

While rubber membranes made from natural rubber or EPDM are prevalent, silicone rubber membranes offer distinct advantages:

- Better Temperature Range: Unlike natural rubber, silicone membranes perform reliably at both high and low temperatures.

- Enhanced Chemical Stability: Silicone resists a broader spectrum of chemicals, reducing degradation over time.

- Superior Longevity: Longer service life in demanding environments due to outstanding weatherability and chemical resistance.

- Flexibility at Low Temperatures: Maintains flexibility in colder conditions where other rubber types stiffen or crack.

Applications of Silicone Rubber Membranes in Business

The broad applicability of silicone rubber membranes makes them a preferred choice in multiple industry segments. Below are some of the most prominent applications:

1. Vacuum Systems & Equipment

In vacuum technology, membranes serve as vital sealing components in vacuum chambers, pumps, and presses. Their ability to withstand repeated cycles of vacuum and pressure without losing integrity makes them ideal for high-precision manufacturing processes.

2. Seals & Gaskets

Silicone membranes are extensively used as seals in machinery exposed to temperature fluctuations, chemical exposure, or outdoor environments. Their resilience against aging contributes to reduced maintenance costs and downtime.

3. Medical & Healthcare

Due to biocompatibility and chemical stability, silicone rubber membranes are utilized in medical devices, including blood pressure cuffs, breathing apparatus, and implantable components.

4. Food & Pharmaceutical Industry

Certifications allowing for food-grade applications enable silicone membranes to serve as barrier layers and sealants, ensuring safety and hygiene standards are met during manufacturing and packaging.

5. Aerospace & Automotive

In these demanding sectors, silicone membranes are used for insulation, vibration damping, and sealing components exposed to extreme temperature variations and harsh chemicals.

Advantages of Choosing Quality Silicone Membranes for Your Business

Investing in high-quality silicone rubber membranes provides a multitude of benefits that steer your business toward operational excellence:

Enhanced Durability & Longevity

Premium silicone membranes resist wear, tear, UV radiation, and ozone degradation, ensuring long service life even in adverse environments, ultimately reducing replacement and maintenance costs.

Reliable Performance & Safety

Consistent performance across a wide temperature and chemical spectrum guarantees safety, compliance, and process stability—key for industries such as healthcare and food production.

Flexibility & Versatility

Flexible membranes conform to complex shapes and surfaces, enabling seamless integration into diverse systems and machinery without compromising performance.

Environmental Resilience

Silicone membranes are eco-friendly, non-toxic, and often recyclable, aligning with modern sustainability initiatives and regulatory standards.

Buying & Customizing Silicone Rubber Membranes

To get the most benefit from silicone membranes, businesses should consider options such as:

- Thickness & Size: Determined by specific application needs; thicker membranes provide more durability, while precise sizing ensures a better fit.

- Reinforcements: Options like fabric or wire reinforcements can enhance tensile strength and dimensional stability.

- Coatings & Surface Treatments: Additional coatings can enhance chemical resistance or reduce friction.

- Custom Shapes & Designs: Tailored membranes for complex geometries or special sealing requirements ensure optimal performance.

At vacuum-presses.com, customers can explore a broad selection of buy membranes, including a premium range of silicone rubber membranes, Rubber Membranes, and natural rubber membranes. Our dedicated team offers expert guidance to help you choose the right product for your industrial needs.

Why Choose vacuum-presses.com for Your Silicone Rubber Membranes?

As a leading supplier, vacuum-presses.com provides:

- High-Quality Materials: Sourced from top manufacturers ensuring durability and consistency.

- Customized Solutions: Tailored to meet your specific technical requirements.

- Competitive Pricing: Cost-effective options without compromising quality.

- Technical Support & Expertise: Our team offers detailed consultations and after-sales support.

Future Trends & Innovations in Silicone Membrane Technologies

The field of silicone rubber membranes continues to evolve, driven by innovations aimed at enhancing performance and sustainability. Emerging trends include:

- Advanced Reinforcement Techniques: Incorporating nanomaterials for increased tensile strength and wear resistance.

- Biodegradable & Eco-Friendly Formulations: Developing sustainable membranes that lessen environmental impact.

- Smart Membranes: Integration with sensors for real-time monitoring of performance and health status.

- Enhanced Customization: Increased automation in manufacturing to produce highly precise and application-specific products.

Conclusion: Opt for Excellence with Silicone Rubber Membranes

Choosing the right silicone rubber membrane is a critical decision for any business aiming to improve system reliability, reduce costs, and achieve superior product quality. With their unmatched properties and broad application spectrum, silicone membranes are a smart investment for modern industries. By partnering with trusted suppliers like vacuum-presses.com, your business can access top-tier materials, innovative solutions, and expert support to elevate your operations.

Leverage the versatility, durability, and performance of high-quality silicone rubber membranes today, and stay ahead in the competitive industrial landscape.